A battery pack can be formed by connecting several lithium batteries in series, which can not only supply power to various loads, but also can be charged normally with a matching charger. Lithium batteries do not require any battery management system (BMS) to charge and discharge. So why are all lithium batteries on the market added with BMS? The answer is safety and longevity.

The battery management system BMS (Battery Management System) is used to monitor and control the charging and discharging of rechargeable batteries. The most important function of a lithium battery management system BMS is to ensure that the battery remains within a safe operating range and to take immediate action if any single battery starts to exceed the limit. If the BMS detects that the voltage is too low, it will disconnect the load, and if the voltage is too high, disconnect the charger. It will also check that each cell in the pack has the same voltage and drop any that are higher than the other cells. This ensures that the battery doesn’t reach dangerously high or low voltages – which is often the cause of the lithium battery fires we see in the news. It can even monitor the temperature of the battery and disconnect the battery pack before it gets too hot and catches fire. So, the battery management system BMS is to keep the battery protected rather than purely relying on a good charger or correct user action.

Why don’t lead-acid batteries (AGM, gel batteries, deep cycle, etc.) require a battery management system? The components of lead-acid batteries are less flammable and they are much less likely to catch fire if there is a problem with charging or discharging. But the main reason has to do with the behavior when the battery is fully charged. Lead-acid batteries are also made of cells connected in series; if one cell is charged slightly more than the other cells, it will only allow current to pass until the other cells are fully charged, while maintaining a reasonable voltage by itself, etc. Batteries catch up. In this way, the lead-acid battery “self-balances” as it charges.

Lithium batteries are different. The positive electrode of the rechargeable lithium battery is mostly lithium ion material. Its working principle determines that during the charging and discharging process, the lithium electrons will run to both sides of the positive and negative electrodes again and again. If the voltage of the single cell is allowed to be higher than 4.25v (except for high voltage lithium batteries), the anode microporous structure may collapse, the hard crystalline material may grow and cause a short circuit, and then the temperature will rise rapidly, which will eventually lead to a fire. When a lithium cell is fully charged, the voltage rises suddenly and can quickly reach dangerous levels. If the voltage of a cell in a battery pack is higher than other cells, this cell will first reach the dangerous voltage during the charging process, and the overall voltage of the battery pack has not reached the full value at this time, the charger will not stop charging . Therefore, the first cell to reach the dangerous voltage poses a safety risk. Therefore, controlling and monitoring the overall voltage of the battery pack is not sufficient for lithium-based chemistries, the voltage of each individual cell that makes up the battery pack must be checked by the BMS.

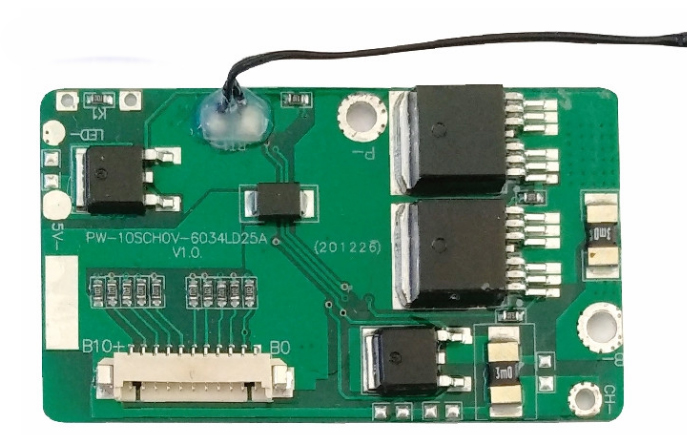

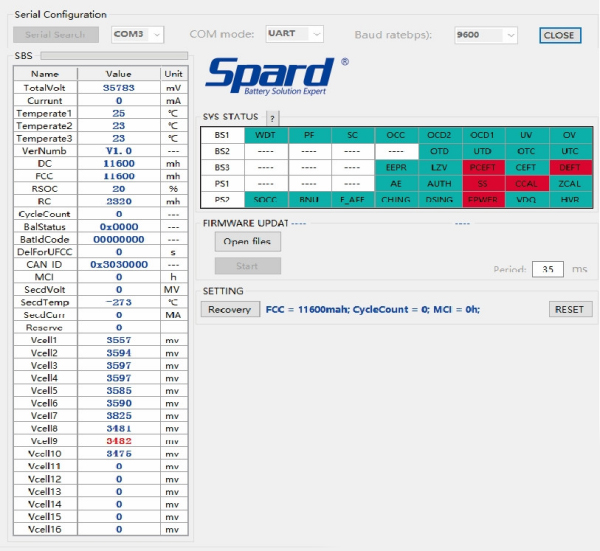

In a narrow sense, the battery management system BMS is used for the protection of large battery packs. The typical use is lithium iron phosphate power batteries, which have protection functions such as overcharge, overdischarge, overcurrent, short circuit, and cell balance. Communication ports, data input and output options and other display functions are required. For example, the communication interface of Xinya’s professional customized BMS is as follows.

In a broad sense, a Protection Circuit Board (PCB), sometimes called a PCM (Protection Circuit Module), is a simple battery management system BMS. Typically used for small battery packs. Typically used for digital batteries, such as mobile phone batteries, camera batteries, GPS batteries, heating clothes batteries, etc. Most of the time, it is used for 3.7V or 7.4V battery pack, and it has four basic functions of overcharge, overdischarge, overcurrent, and short circuit. Some batteries may also require PTC and NTC.

Therefore, to ensure the safety and long service life of lithium battery packs, a battery management system BMS with reliable quality is really needed.

Post time: Mar-31-2022